CMMI - Framework Interactions

This section addresses the interactions among process areas which help visualization of the enterprise view of process improvement. The

process areas discussed and illustrated include the IPPD and supplier

sourcing material that is specific to models that include the IPPD and

supplier sourcing disciplines.

Where the Integrated Project Management (IPM) process area is

mentioned in this chapter, it will refer to IPM for IPPD. Interactions of

the IPM for IPPD process area with the Integrated Teaming (IT) and

Organizational Environment for Integration (OEI) are covered.

Pocess areas this way to address the manner in which they interact and have an effect on one

another regardless of their defined group. For example, the Decision

Analysis and Resolution process area provides specific practices

addressing formal evaluation that are used in the Technical Solution

process area for selecting a technical solution from alternative

solutions. Technical Solution is an Engineering process area and

Decision Analysis and Resolution is a Support process area.

The Engineering process areas were written in a general engineering

terminology so any technical discipline involved in the product

development process (e.g., software engineering, mechanical

engineering) can use them for process improvement. The Process

Management, Project Management, and Support process areas also

To apply CMMI properly, the interactions that exist among CMMI model components need to be understood.

Process Management

Process Management process areas contain the cross-project activities

related to defining, planning, resourcing, deploying, implementing,

monitoring, controlling, appraising, measuring, and improving

processes.

Basic Process Management Process Areas

The basic Process Management process areas provide the organization

with a basic capability to document and share best practices,

organizational process assets, and learning across the organization.

Figure 1 illustrates the interactions among the basic

Process Management process areas and with other process area

categories.

Organizational Process Focus

- helps the organization to plan and implement organizational

process improvement based on an understanding of the current

strengths and weaknesses of processes and process

assets. Candidate process improvements are

obtained through process-improvement

proposals, measurement of the processes, lessons learned in

implementing the processes, and results of process appraisal and

product evaluation activities.

- establishes and

maintains the set of standard processes and other assets

based on the process needs and objectives of the organization. These

other assets include descriptions of processes and process elements,

descriptions of life-cycle models, process tailoring guidelines, process-related

documentation, and data. Projects tailor the organizationís set of

standard processes to create their defined processes. The other assets

support tailoring as well as implementation of the defined processes.

Experiences and work products from performing these defined

processes, including measurement data, process descriptions, process

artifacts, and lessons learned, are incorporated as appropriate into the

organizationís set of standard processes and other assets.

Organizational Training

- Identifies the strategic

training needs of the organization as well as the tactical training needs

that are common across projects and support groups. In particular,

training is developed or obtained that develops the skills required to

perform the organizationís set of standard processes. The main

components of training include a managed training-development

program, documented plans, personnel with appropriate knowledge,

and mechanisms for measuring the effectiveness of the training

program.

Organizational Process Definition

- Establishes and

maintains the organizationís set of standard processes and other assets

based on the process needs and objectives of the organization. These

other assets include descriptions of processes and process elements,

descriptions of life-cycle models, process tailoring guidelines, process-related

documentation, and data. Projects tailor the organizationís set of

standard processes to create their defined processes. The other assets

support tailoring as well as implementation of the defined processes.

Experiences and work products from performing these defined

processes, including measurement data, process descriptions, process

artifacts, and lessons learned, are incorporated as appropriate into the

organizationís set of standard processes and other assets.

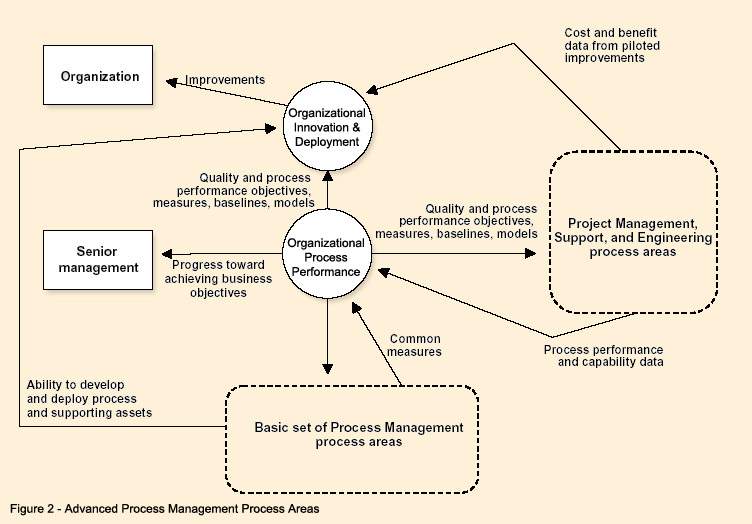

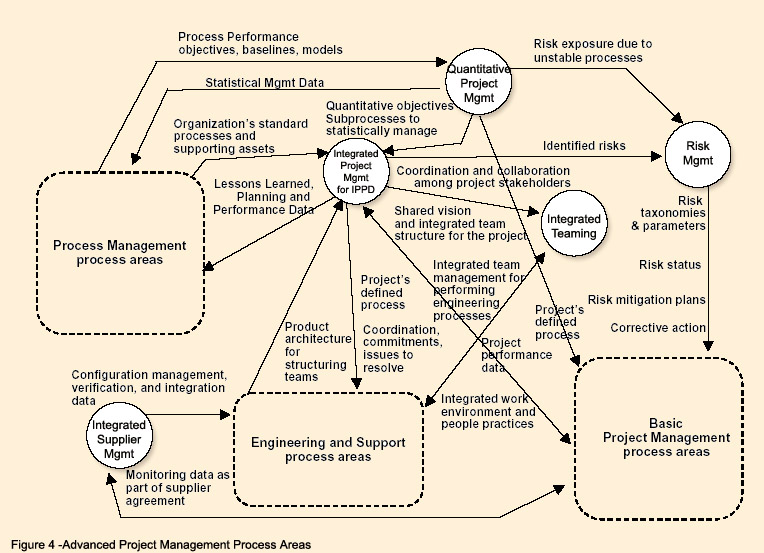

Advanced Process Management Process Areas

The advanced Process Management process areas provide the

organization with an advanced capability to achieve its quantitative

objectives for quality and process performance.

Each of the advanced Process Management process

areas is strongly dependent on the ability to develop and deploy

process and supporting assets. The basic Process Management

process areas provide this ability. [Note].

Organizational Process Performance

- derives quantitative objectives for quality and process

performance from the organizationís business objectives. The

organization provides projects and support groups with common

measures, process performance baselines, and process performance

models. These additional organizational support assets support

quantitative project management and statistical management of critical

sub-processes for both projects and support groups. The organization

analyzes the process performance data collected from these defined

processes to develop a quantitative understanding of product quality,

service quality, and process performance of the set of

standard processes.

Organizational Innovation and Deployment

- selects and deploys proposed incremental and innovative improvements that

improve the organizationís ability to meet its quality and process performance

objectives. The identification of promising incremental and

innovative improvements should involve the participation of an

empowered workforce aligned with the business values and objectives

of the organization. The selection of improvements to deploy is based

on a quantitative understanding of the potential benefits and costs from

deploying candidate improvements, and the available funding for such

deployment.

![[To top of Page]](../images/up.gif)

Project Management

Project Management process areas cover the project management

activities related to planning, monitoring, and controlling the project.

Basic Project Management Process Areas

Address the basic

activities related to establishing and maintaining the project plan,

establishing and maintaining commitments, monitoring progress against

the plan, taking corrective action, and managing supplier agreements.

Project Planning

- includes

developing the project plan, involving stakeholders appropriately,

obtaining commitment to the plan, and maintaining the plan. When

using an IPPD approach, stakeholders represent not just the technical

expertise for product and process development, but also the business

implications of the product and process development.

- Planning begins with requirements that define the product and project

(ďWhat to BuildĒ in the figure). The project plan covers the various

project management and engineering activities that will be performed by

the project. The project will review other plans that affect the project

from various relevant stakeholders and establish commitments with

those relevant stakeholders for their contributions to the project. For

example, these plans cover process appraisals, product evaluations,

configuration management, and measurement and analysis.

Project Monitoring and Control

- includes monitoring

activities and taking corrective action. The project plan specifies the

appropriate level of project monitoring, the frequency of progress

reviews, and the measures used to monitor progress. Progress is

primarily determined by comparing progress to the plan. When actual

status deviates significantly from the expected values, corrective

actions are taken as appropriate. These actions may include re-planning.

Supplier Agreement Management

- addresses the

need of the project to effectively acquire those portions of work that are

produced by suppliers. Once a product component is identified and the

supplier who will produce it is selected, a supplier agreement is

established and maintained that will be used to manage the supplier.

The supplierís progress and performance are monitored. Acceptance

reviews and tests are conducted on the supplier-produced product

component.

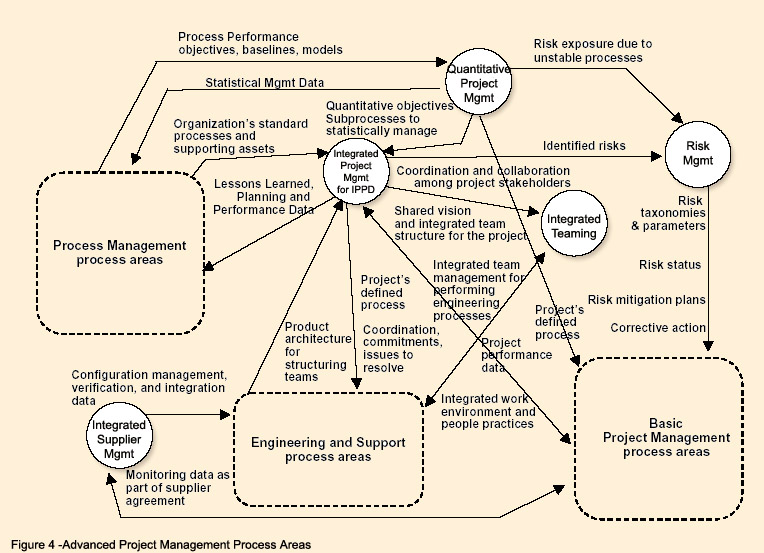

Advanced Project Management Process Areas

Address activities

such as establishing a defined process that is tailored from the

organizationís set of standard processes, coordinating and collaborating

with relevant stakeholders (including suppliers), risk management,

forming and sustaining integrated teams for the conduct of projects, and

quantitatively managing the projectís defined process. Each of the advanced Project Management process

areas is strongly dependent on the ability to plan, monitor, and control

the project provide by the basic Project Management process areas. Each of the advanced Project Management process

areas is strongly dependent on the ability to plan, monitor, and control

the project established through the basic Project Management process areas.

Integrated Project Management

- Both versions of the Integrated Project Management process area (IPM

and IPM for IPPD) establish and maintain the projectís defined process

that is tailored from the organizationís set of standard processes. The

project is managed using the projectís defined process. The project

uses and contributes to the organizationís process assets.

- The project ensures that the relevant stakeholders associated with the

project coordinate their efforts in a timely manner. It does this by

providing for the management of stakeholder involvement; the

identification, negotiation, and tracking of critical dependencies; and the

resolution of coordination issues within the project with relevant

stakeholders.

Integrated Project Management for IPPD

- This area also creates

the shared vision for the project. This shared vision should align both

horizontally and vertically with both the organizationís and integrated

teamís shared visions, created in the Organizational Environment for

Integration and Integrated Teaming process areas, respectively. These

shared visions collectively support the coordination and collaboration

among stakeholders. Finally, the Integrated Project Management for

IPPD process area implements an integrated team structure to perform

the work of the project in developing a product. This team structure is

typically based on the decomposition of the product itself, much like a

work breakdown structure. This activity is accomplished in conjunction

with the Integrated Teaming process area.

Risk Management

- Although risk identification and monitoring are covered in the Project

Planning and Project Monitoring and Control process areas, the Risk

Management process area takes a more continuing, forward-looking

approach to managing risks with activities that include identification of

risk parameters, risk assessments, and risk handling.

Quantitative Project Management

- Applies quantitative

and statistical techniques to manage process performance and product

quality. Quality and process-performance objectives for the project are

based on those established by the organization. The projectís defined

process comprises, in part, process elements and sub-processes whose

process performance can be predicted. At a minimum, the process

variation experienced by sub-processes that is critical to achieving the

projectís quality and process-performance objectives is understood.

Corrective action is taken when special causes of process variation are

identified.

Integrated Teaming

- The specific practices in the Integrated Teaming process area provide

for the formation and sustainment of each integrated team. Part of

sustaining the team is developing the integrated teamís shared vision,

which must align with the projectís and organizationís shared visions,

developed in the Integrated Project Management for IPPD and

Organizational Environment for Integration process areas, respectively.

The specific practices in the Organizational Environment for Integration

and Integrated Teaming process areas then set the environment for

enabling integrated teamwork. In addition, the Integrated Teaming

process area interacts with other Project Management processes by

supplying team commitments, work plans, and other information that

forms the basis for managing the project and supporting risk

management.

Integrated Supplier Management

- Proactively

identifies sources of products that may be used to satisfy project

requirements and monitors selected supplier work products and

processes while maintaining a cooperative project-supplier relationship.

The specific practices of the Integrated Supplier Management process

area cover selecting potential sources of products, evaluating those

sources to select suppliers, monitoring selected supplier processes and

work products, and revising the supplier agreement or relationship as

appropriate. The Integrated Supplier Management process area works

closely with the Supplier Agreement Management process area during

the supplier selection process. Integrated Supplier Management also

shares monitoring information with the Engineering and Support

process areas in the form of technical solution, product integration, and

validation data as well as process and product quality assurance and

configuration management data.

![[To top of Page]](../images/up.gif)

Engineering

Cover the development and maintenance

activities that are shared across engineering disciplines (e.g., systems

engineering and software engineering). The six process areas in the

Engineering process area category have inherent interrelationships which stem from applying a product development

process rather than discipline-specific processes such as software

engineering or systems engineering.

The Engineering process areas integrate software-engineering and

systems-engineering processes into a product-oriented process improvement

scenario. Improving product development processes

targets essential business objectives, rather than specific disciplines.

This approach to processes effectively avoids the tendency toward an

organizational ďstovepipeĒ mentality.

The technical foundation for IPPD is grounded in a robust systems engineering

approach that encompasses development in the context of

the phases of the productís life, such as that provided in the

Engineering process areas of the CMMI-SE/SW model. Thus, the

implementation of IPPD provides amplifications to specific practices in

the Engineering process areas that emphasize concurrent development

The Engineering process areas apply to the development of any

product or service in the engineering development domain (e.g.,

software products, hardware products, services, or processes).

Requirements Development

- Identifies customer

needs and translates these needs into product requirements. The set of

product requirements is analyzed to produce a high-level conceptual

solution. This set of requirements is then allocated to a set of product component

requirements. Other requirements that help define the

product are derived and allocated to product components. This set of

product and product-component requirements clearly describes the

product's performance, design features, verification requirements, etc.

in terms the developer understands and uses.

- Supplies requirements to

the Technical Solution process area, where the requirements are

converted into the product architecture, product-component design, and

the product component itself (e.g., coding, fabrication). Requirements

are also supplied to the Product Integration process area, where

product components are combined and interfaces are ensured to meet

the interface requirements supplied by Requirements Development.

Requirements Management

- maintains the

requirements. It describes activities for obtaining and controlling

requirement changes and ensuring that other relevant plans and data

are kept current. It provides traceability of requirements from customer

to product, to product component.

- ensures that changes to requirements are

reflected in project plans, activities, and work products. This cycle of

changes may impact all the other Engineering process areas; thus

requirements management is a dynamic and often recursive sequence

of events. Establishment and maintenance of the Requirements

Management process area is fundamental to a controlled and

disciplined engineering design process.

Technical Solution

- develops technical data packages

for product components that will be used by the Product Integration

process area. The examination of alternative solutions, with the intent of

selecting the optimum design based upon established criteria, is

expected. These criteria may be significantly different across products,

depending on product type, operational environment, performance

requirements, support requirements, and cost or delivery schedules.

The task of selecting the final solution makes use of the specific

practices in the Decision Analysis and Resolution process area.

- relies on the specific practices in

the Verification process area to perform design verification and peer

reviews during design and prior to final build.

Verification

- ensures that selected work products meet

the specified requirements. The process area selects work

products and verification methods that will be used to verify work

products against specified requirements. Verification is generally an

incremental process, starting with product-component verification and

usually concluding with verification of fully assembled products.

- addresses peer reviews - a proven

method for removing defects early and provide valuable insight into the

work products and product components being developed and

maintained.

Validation

- incrementally validates products against

the customerís needs. Validation may be performed in the operational

environment or a simulated operational environment. Coordination with

the customer on the validation requirements is one of the most essential

elements of this process area.

- The scope of the Validation process area includes validation of

products, product components, selected intermediate work products,

and processes. The product, product component, selected intermediate

work product, or process may often require re-verification and revalidation.

Issues discovered during validation are usually resolved in

the Requirements Development or Technical Solution process areas.

Product Integration

- establishes the expected specific

practices associated with generating the best possible integration

sequence, integrating product components and delivering the product to

the customer.

- uses the specific practices of both Verification and

Validation in implementing the product integration process. Verification

verifies the interfaces and interface requirements between product

components prior to product integration. This is an essential event in

the integration process. During product integration in the operational

environment, the specific practices of the Validation process area are

used.

Engineering Process Areas and Recursion

All Engineering process areas support recursion in their the product architectures. An example is the Establish

Product Integration Procedures and Criteria specific practice in the

Product Integration process area. For a product with many complex

product components, this specific practice would be applied to the

product components of the complete product delivered to the customer

as well as to the product components assembled to form the product,

and so on. Thus, this specific practice is applied to as many levels as

necessary to integrate everything that the product comprises.

There is no specific practice that forces recursive process application.

Rather, the specific practices are written in a fashion that ďexpectsĒ

process application throughout the product architecture. When

implementing the specific practices of an Engineering process area, they

must be interpreted according to how they meet the needs of the product being delivered. The approach provides a generic set of expectations that can be applied at

any level of product detail rather than as enabling recursive behavior of

a process. Either description of this approach is appropriate.

There are a number of advantages gained by this approach. For

example, the Engineering process areas can be applied to a product

that has several layers of product components and ensure that the

specific practices will address each layer. Thus, different segments of a

very large project can be appraised using the same model.

![[To top of Page]](../images/up.gif)

Support

Support process areas cover the activities that support product

development and maintenance. They encompass processes that are used in the context of performing other processes. In

general the Support process areas address processes that are targeted

towards the project, and may address processes that apply more

generally to the organization. For example, Process and Product

Quality Assurance can be used with all the process areas to provide an

objective evaluation of the processes and work products described in all

of the process areas.

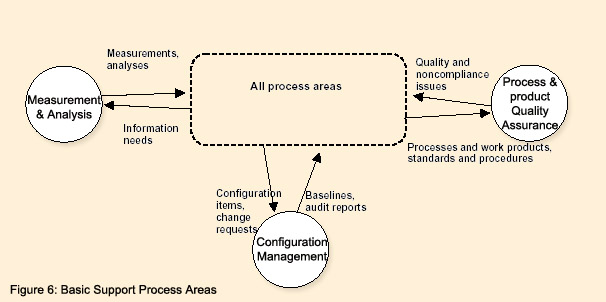

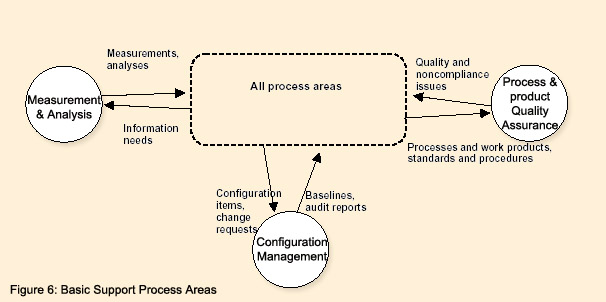

Basic Support Process Areas

Address basic support functions that

are used by all process areas. Although all Support process areas rely

on the other process areas for inputs, the basic Support process areas

provide support functions that are covered by generic practices.

Measurement and Analysis

- supports all process

areas by providing specific practices that guide projects and

organizations in aligning measurement needs and objectives with a

measurement approach that will provide objective results. These results

can be used in making informed decisions and taking appropriate

corrective actions.

Process and Product Quality Assurance

- supports all

process areas by providing specific practices for objectively evaluating

performed processes, work products, and services against the

applicable process descriptions, standards, and procedures and

ensuring that any issues arising from these reviews are addressed.

Process and Product Quality Assurance supports the delivery of high quality

products and services by providing the project staff and all levels

of managers with appropriate visibility into, and feedback on, the

processes and associated work products throughout the life of the

project.

Configuration Management

- supports all process

areas by establishing and maintaining the integrity of work products

using configuration identification, configuration control, configuration

status accounting, and configuration audits. The work products placed

under configuration management include the products that are

delivered to the customer, designated internal work products, acquired

products, tools, and other items that are used in creating and describing

these work products. Examples of work products that may be placed

under configuration management include plans, process descriptions,

requirements, design data, drawings, product specifications, code,

compilers, product data files, and product technical publications.

Advanced Support Process Areas

The advanced Support process areas provide the projects and

organization with an advanced support capability. Each of these

process areas relies on specific inputs or practices from other process

areas.

Causal Analysis and Resolution

- the project

strives to understand the common causes of variation inherent in

processes and remove them from the projectís processes, as well as

using this knowledge to continually improve organizational processes. Both the defined processes and the set of

standard processes are targets of these improvement activities.

Decision Analysis and Resolution

- supports all the

process areas by providing a formal evaluation process that ensures

that alternatives are compared and the best one is selected to

accomplish the goals of the process areas.

Organizational Environment for Integration

- establishes the approach and environment for the implementation of

IPPD. The environment is established by obtaining, adapting, or

developing processes that facilitate effective integrated team behavior

as well as stakeholder communication and collaboration, creating the

organizationís shared vision, and managing people to promote

integrative behavior. Specific practices in the Organizational

Environment for Integration process area promote both team and

individual excellence while enabling and rewarding integration across all

business and technical functions in the execution of the projects.

![[To top of Page]](../images/up.gif)

Tailoring a Model for an Organization

An organization should develop a CMM model approprIate for their organization in order to undertake benchmarking both over time within the organization and to permit maturity/capability comparison with similar industry organizations. Tailoring is the construction of this approach and methodology within the organization.

Criteria for Tailoring Internal Process Improvement

Tailoring should focus on identifying the process areas and practices that support

business needs and objectives. For internal process improvement, restricting or expanding

the scope of an organizationís or projectís improvement effort (including

appraisals) may be desirable. The tailoring may address individual disciplines, process

areas, maturity levels, and/or capability levels.

Given a CMMIís focus on the essential

characteristics of an effective process, most process areas

and practices in a model typically would need to be addressed. The

wholesale exclusion of fundamental processes or specific practices should be viewed with caution. Organizations and projects implementing less than a full set of process

areas, goals, or practices may still achieve significant value from a

CMMI model, but, because of the interrelationship of model

components, exclusion of a significant number of process areas, goals,

or practices may diminish the benefits achieved. In addition, the degree

of comparability of appraisal results is directly related to the extent to

which a model and appraisal method have been tailored.

Model Tailoring Criteria for Benchmarking

Use of CMMI models for benchmarking purposes permits comparison

of process appraisal results across an industry via state-of-the-practice

reports (eg. ITIL) or across a group of organizations such as potential suppliers.

Applied in this way, tailoring must ensure consistency (ie. fair treatment) in the ratings

produced from the models used in multiple appraisals. As a result,

model tailoring for benchmarking is significantly constrained[Note].

- Criteria:

Focus on a Specific Maturity/Capability Level

Process areas include required and expected model components

and thus may not be excluded other than to omit those that are

outside the scope of an appraisal. For example, when an

organization uses a staged representation, process areas at

maturity levels 4 and 5 may be omitted for an appraisal focused on

maturity level 3, whereas all process areas for maturity levels 2 and

3 would typically be selected. When using a continuous

representation, process areas outside the scope of the target

profile may be omitted, but doing so will compromise the

benchmarking opportunities provided by equivalent staging.

Process Areas Not Performed by the Organization

Process areas, in some circumstances, may be determined to be

ďnot applicableĒ if the process area is, in fact, outside of the

organizationís scope of work. An example of a process area that

might be excluded from an appraisal using a staged representation

would be Supplier Agreement Management, a process area that

may not be applicable in the absence of suppliers of products and

services external to the organization that are critical to the

development effort. A maturity level rating could still be determined;

however, that maturity level rating must also include mention of the

ďnot applicableĒ process area. Conversely, when using a

continuous representation, process areas may be selected for

exclusion if they are not within the organizationís scope of work or

of the process-improvement effort. Care must be taken, however,

that process areas providing the foundation for other process areas

important to the organization are not excluded. Furthermore, even

though an organization uses a continuous representation, if it

wishes to use equivalent staging it must adhere to the tailoring

guidelines practiced by users of the staged representation.

Insufficient Information to determine Rating

A process area is designated as ďnot ratedĒ if it is outside the

appraisal scope or if insufficient data is available to satisfy the

data-coverage criteria. A maturity level cannot be determined if

process areas at that maturity level (or below) are ďnot rated.Ē

Process Area Goals

Goals are required and thus cannot be excluded from those

process areas included in the scope of a process-improvement or

appraisal effort. Goals reflect the minimum requirements for

satisfying a process area. If a process area is applicable, each of

its goals is applicable. Goals work together to support a process

area and may not be individually designated as ďnot applicable.Ē

Substituting Practices which Meet Goals

Specific practices and generic practices are expected to be

implemented as typical activities necessary to implement and

institutionalize the goals of the process area. However, appropriate

alternative practices may be substituted for specific practices

and/or generic practices if the alternatives are effective in

implementing and institutionalizing the goals.

Informative Components

All other model components (subpractices, examples,

amplifications, elaborations, and/or references) contained in CMMI

models are informative and are provided solely for guidance in

implementation.

Smaller Projects

While the CMMI models were written for use by all types of organizations, for small organizations a CMMI model must be interpreted. In

the case of small, three- to six-month projects, a high-level plan is

typically available that has been developed for a group of projects. This

high-level plan defines the organization, resources, training,

management participation, and quality assurance reporting descriptions

for all projects.

Conversely, in the project plan, the detailed planning of the project,

such as the schedule, tasks, and resources, are defined. Often the

project plan also contains plans for other supporting functions, such as

quality assurance and configuration management. A four-person project

might expect to develop a project plan that is only a few pages long.

In small projects, meetings take place more frequently, take less time,

and cover more details. The schedule may contain daily activities, and

may be monitored in weekly meetings. The schedule may change

weekly and be controlled.

In a small team, the customer usually knows the entire team and feels

comfortable calling any member of the team to propose or discuss a

change. The team must decide up front how to handle these informal

calls from the customer. Once team members have decided on an

approach, it should be documented and communicated to the customer.

Tailoring Options

The major appraisal-tailoring options for a CMMI appraisal include the

following:

- Establishing the appraisal scope, including the organizational entity to be appraised, the CMMI process areas to be investigated, and the level to be appraised

- Selecting the appraisal method

- Selecting the appraisal team members

- Selecting appraisal participants from the appraisal entity to be interviewed

- Establishing appraisal outputs (for example, ratings, instantiation specific findings)

- Establishing appraisal constraints (for example, time spent on site)

In addition to these appraisal-tailoring options, the CMMI appraisal

method description details a number of specific appraisal-tailoring

options driven by considering the objectives of a particular appraisal

and the business objectives of the organization and/or instantiation.

Documentation of CMMI appraisal plans and results must always

include a description of the appraisal-tailoring options selected, as well

as any model tailoring. Such documentation will enable a determination

to be made of the comparability of appraisal results across

organizations.

![[To top of Page]](../images/up.gif)

![]()

![]()

![]()

![]()